|

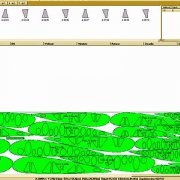

Digital patterns of a glider are prepared (optimized) in special CAD system. Each piece is checked and prepared for the right position in the cut plan (layout plan – see picture number 2); the rules for positioning in the plan are set up (warp and weft rotation, flip or flop positioning,) each piece is assigned with material it will be made of. Layout rules for nesting are very strict as all the pieces must meet demands of the load and shock tests and must comply with the quality of rib stop material.It is right now when we make the design for the glider, the cross points are checked and optimized (in fact the tiny dots that we use to put the pieces together when the glider is assembled), pieces are marked with numbers and letters. Each glider (depending on the number of cells) has got 430 pieces (FIDES 2) or even 965 (ERIS). |

|

All the pieces are prepared in the cut plan which is in the fact the layout plan for final cutting. Nesting of the pieces is done automatically or manually to reach the best usage of the material. If you play the game called TETRIS well, then you end up with the efficiency of the material usage at about 94%, or, to put it in a different way – wastage of as less as 6%. |

|

The pieces are cut using the CNC cutter. All the pieces are marked (numbered) and cut at same time. Using the cutter we avoid all the occasional mistakes, we know exactly the time of the cutting and we have the full control of the quality in time. The portion of labour and the portion of mistakes done my humans are minimized… |

|

The fabric is transported to the conveyor belt through „edge control“ device, which, using the technology of the photocell, levels the edge of the material. The fabric is fixed in the cut window by a vacuum pump. Even if the total length of the plan is more than 30 meters, the diagonal shift of the material is minimised… |

|

Each piece is being sorted and double checked at the light table for possible material defects. The bench mark materials are to be used for the reference and the final decision if the material on the distinctive piece is OK or not. |

|

All the pieces are sorted out according to the rules of the production batches – the tension tapes, ribs reinforcements and model name letters are prepared and thus, the set is ready for stitching… |

|

Before the final assembly, all the preparations takes place – loops and reinforcements are ready, the design pieces are stitched together to make the final upper and bottom panels… |

|

It is only now when we can start the final assembly – it is necessary to pre stitch the wingtips and start the assembly, i.e. stitch with millimetre precision (this is why we use the check points) sometimes five layers of cloth (rib, two diagonals and the panels on each side). |

|

During the whole process there are many quality control checks. The results are recorded in the quality list. |

|

The whole assembly process s finished by the final trailing edge webbing and adding the brake loops. |

|

Meanwhile the lines are prepared – according to the lists each line is measured, marked and equipped with the loop for the fixing the lines together. |

|

Before the lines assembly, the production number of the glider is recorded and the canopy id provided with the production tag. The canopy is checked by simulation the air flow, all the diagonal positions are checked – when the defect piece is recorded, the pieces are immediately replaced for the new ones… The defect average rate is less than 0, 5% and we still aim for less than 2 gliders per 1000 produced… |

|

The canopy is provided with lines. The fork system is created by threading the line into the cascade system. The risers are attached and he speed system hook is prepared… |

|

It is necessary to stabilize the lines by loading them with defined load – the definition is different for each line diameter. When the line is pre stretched, the core is stabilized and the knots are fixed. |

|

Now the glider geometry is measured under the tension of 5 kg, the symmetry is checked. Any difference is immediately corrected, the line is pre tensioned again and measured. The results are recorded and filed for future reference… |

|

The gliders are ready for test flight simulation. When, the general quality is checked. There are 38 check points of the final checking. |

|

Test flight protocol is signed, all the production evidence is filed, and the production number is double checked and recorded. The canopy is cleaned (if needed), packed, provided with model and size tags, stored in the inner bag and gets ready for expedition to the customers. |